How do you go about problem solving in your organisation? Do you have a process or just “wing it” in the hope that inspiration will deliver a permanent solution?

Organisations that follow a standardised process for problem solving invariably get to the root cause and develop a permanent countermeasure preventing a re-occurrence of the problem.

I think it is helpful to think of problem solving as being a team exercise which takes place in eight steps. Start by giving a small multi-discipline team some basic problem solving skills training.

Let’s consider how this team might approach a customer quality issue. Most organisations have a measure of customer quality in terms of the number of complaints raised, credit notes issued or bad parts shipped.

The first step is to define the problem in a manner that relates it to the desired performance level and identifies the current gap in performance.

1. Clarify the problem

- What is the current situation?

- What is the ideal situation?

- What is the performance gap?

It is always best to “speak with data” so list the problems reported in order of priority (in terms of the impact on the desired outcome; zero complaints/defects, <10 credit notes raised/month) and look at trend data over a 6 to 12 month period. This will show which products/issues are causing the most problems.

2. Break down the problem

- List each individual problem

- Quantify each problem

- Rank in order of impact on desired outcome

Then use the data to select the issue to be tackled and use it to set some specific improvement goals: an improvement (reduction) in the number of complaints with a time bound commitment for delivery.

3. Set a target

- Use the data to select what you are going to tackle

- Determine what you are going achieve (how much improvement) and by when

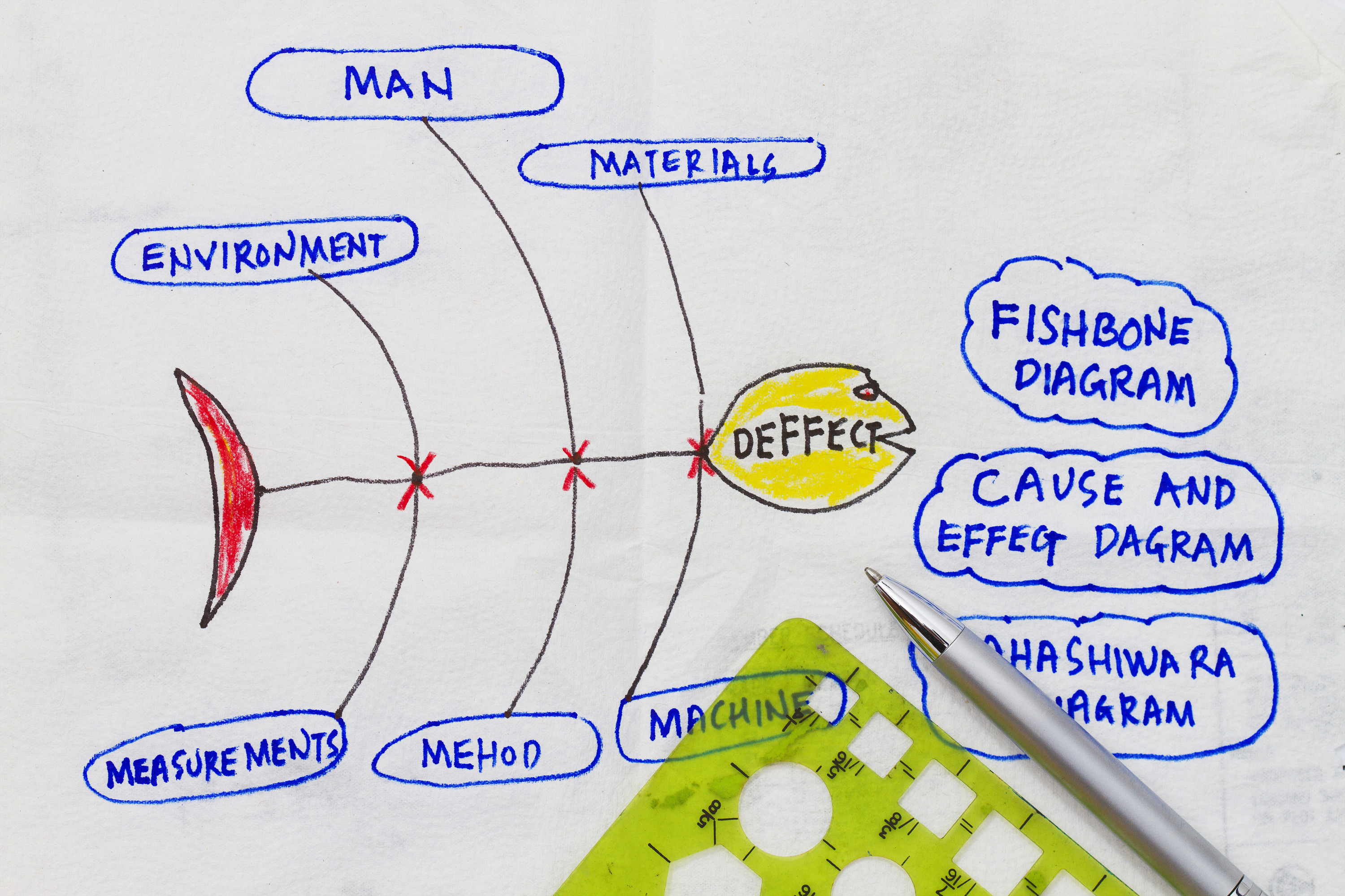

Now the team should list all possible causes of the problem, sorting then in terms of probable cause: People, Method, Material, Equipment, Environment and Measurement. It helps to visualise the analysis by mapping all the possible causal factors on an Ishikawa cause and effect “fishbone” diagram. Test each identified probable cause to determine if it is the real root cause.

4. Analyse the root cause

- List all possible causes of the chosen problem

- Group them by probable cause

- Keep asking “why” until you are at a root cause

Next, develop countermeasures for each identified causal factor and rank them in terms of ease of implementation, cost and time to introduce.

5. Develop countermeasures

- List all possible counter measures

- Rank them in terms of ease of implementation, time to implement and cost

- Choose which will provide the most cost effective solution

Test each identified countermeasure to ensure it delivers the desired improvement and then rigorously plan their introduction to ensure any process or procedure changes take hold.

6. See the countermeasure through

- Plan introduction of any changes to equipment, materials and operating procedures

- Draw up new standard working instructions

- Train people in the new standard work procedures

And to ensure you really have solved the problem set up some regular checks.

7. Monitor both results and processes

- Collect data over a time period

- Audit that the new standard work procedures are being followed

- Compare with the before situation and target goal

- Evaluate if further improvement cycles are necessary

- If necessary repeat the analysis and countermeasure steps

Lastly, once you are satisfied that you have a found the root cause and determined a permanent countermeasure, roll out the learning points across the other teams and processes in your business.

8. Standardise successful processes

- Look at comparable process and operations in your organisation and roll out the new processes and procedures to improve performance

- Share the solution with other work teams

Over time everyone will learn to follow the steps and see the benefits of a standardised approach to problem solving.

This does not come overnight. It takes time to train everyone in the methods and a few events for the teams to gain confidence. But once learnt, you will be amazed at how following a simple problem solving method will improve the performance of your business and delight your customers.